What is Lean PPM?

Lean PPM is a lightweight framework for corporate project portfolio management. The goal of Lean PPM is to develop a portfolio plan using minimal, reliable data and a simple decision-making process. With Lean PPM, companies can answer the question of which projects will be implemented when and with which resources.

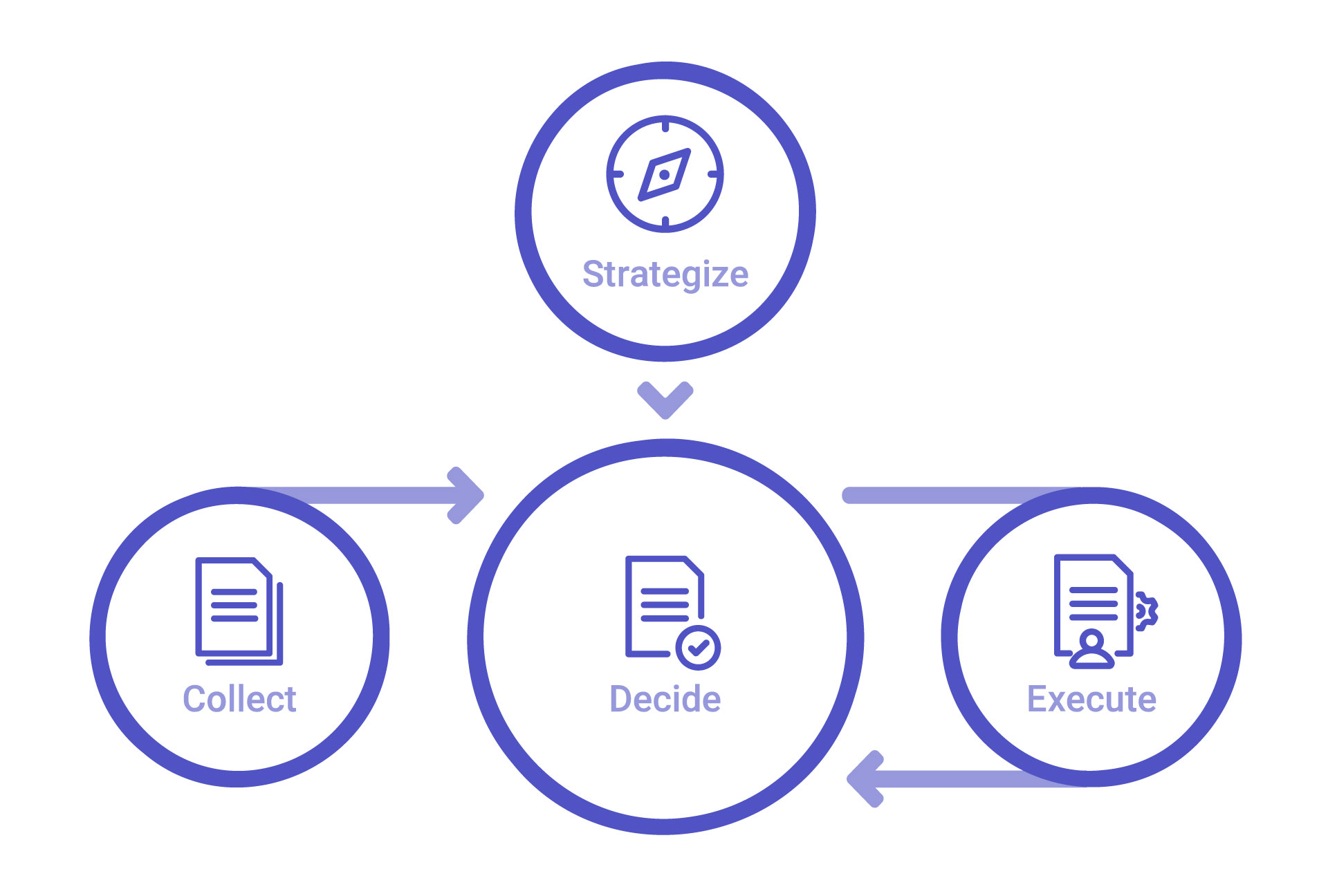

Basic Activities in Lean PPM

The Lean PPM Framework describes four basic activities in project portfolio management. It includes all the necessary processes, meetings and roles that are needed in the respective areas.

- Strategize: Companies align their project portfolio with corporate strategy. They develop criteria for evaluating project proposals to ensure that each project contributes to achieving the company’s goals.

- Collect: Companies collect new project proposals and develop project initiatives. They carry out proposal coaching to improve the quality of the proposals and move them to the next process step.

- Decide: This phase is where the steps all come together. Companies evaluate and prioritize projects, making decisions about resourcing, budgeting and the future composition of the portfolio.

- Execute: Companies implement the agreed-upon portfolio. The goal is to accelerate implementation and resolve obstacles such as resource conflicts.

Benefits of Lean PPM

Companies all over the world use this framework to make their project portfolios more efficient and better aligned with their strategic goals. Some of the key benefits of Lean PPM include:

- Better employee utilization: With Lean PPM, companies can make efficient use of their employees without overloading them.

- More informed decision making: The clear structure and defined processes in Lean PPM enable faster and more informed decision making.

- Improved overview: Lean PPM provides a better overview of the entire project portfolio and enables an understanding of dependencies between projects or resources.

- Flexibility and adaptability: With Lean PPM, companies can respond more quickly and flexibly to changes and adapt to dynamic market conditions.

Where Does the “Lean” in Lean PPM Come From?

The Lean PPM framework is inspired by the principles of Lean Management – a collection of techniques, mindsets and processes for the development and production of industrial goods that emerged from the “Toyota Production System” (TPS). Similar principles are at the forefront of both Lean Management and Lean PPM:

- Team-centered approach: The teams involved are given responsibility for individual production steps, as they have the most information about their projects.

- Value focus: Constantly questioning whether an action or result creates value from the customer and company perspective.

- Pull principle: Teams “pull” work as soon as they have the capacity to do so instead of waiting for the next step at a predetermined time. This helps prevent overload.

- Palette size 1: This principle aims not to deliver a “palette” of results but to provide individual results as quickly as possible.

- Waste avoidance (muda): All activities should be aimed at avoiding waste and creating value instead.

Lean PPM Wins!

Lean PPM represents a modern approach to project portfolio management based on the philosophy of lean management. With its focus on feasibility and value maximization, it provides an effective framework for companies to prioritize and implement their projects.

Discover More Here!

Dive even deeper into project portfolio management! Each article offers valuable insights and expert knowledge that we would like to share with you.

The 7 Forms of Waste in Project Portfolio Management

Lean Project Portfolio Management for Organizations